The Aged Equipment Obstacles

In CPG production, aged equipment is often one of the biggest obstacles to digital transformation. Every packaging facility has legacy assets that still run reliably, but when it comes time to connect them into a modern data strategy, the gaps become obvious.

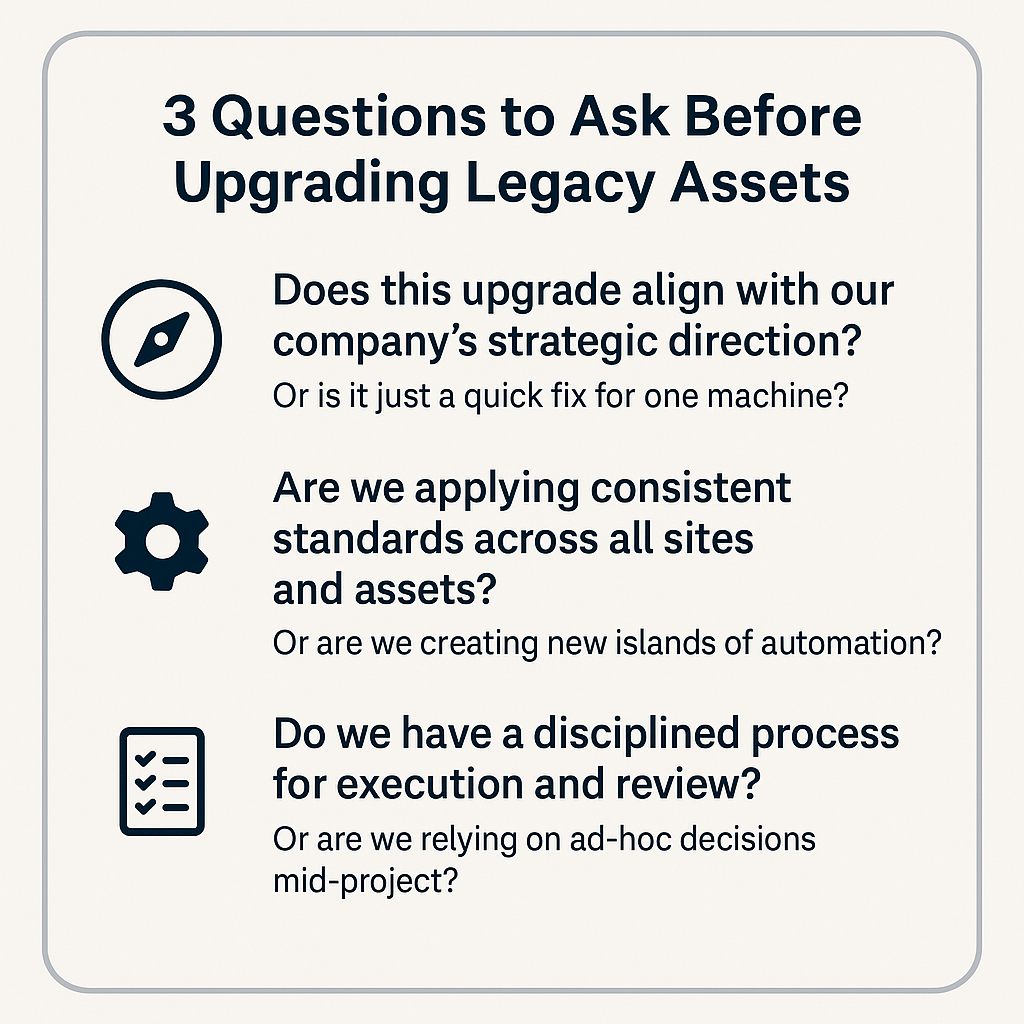

The bigger challenge, though, is not just technical. It’s making sure automation projects stay aligned with the long-term strategic direction of the company. A new dashboard or sensor may provide some short-term insights, but without a structured approach, upgrades risk becoming isolated experiments rather than meaningful steps forward.

Modernizing legacy assets requires more than bolt-on technology. It calls for:

Stable standards so automation integrates seamlessly across sites and assets.

Clear priorities that remain consistent rather than shifting mid-project.

Disciplined execution and systematic management checkpoints that ensure real IT/OT integration and useful data harvesting.

The importance of this discipline is reinforced by industry research. According to PMMI, nearly 70% of manufacturers cite legacy equipment as the single biggest barrier to IT/OT integration. That statistic underscores the reality: this isn’t just a “technology problem.” It’s a challenge of leadership, alignment, and execution.

https://www.pmmi.org/report/2025-beverage-industry-packaging-trends

The same consistency we expect from process control should also guide how we approach automation upgrades. When leadership provides steady direction, standards are enforced, and projects are managed with rigor, legacy operations can make the leap into Industry 4.0. The result is more production with less effort — not by chance, but by design.

How is your team approaching the challenge of bringing legacy equipment into a connected future?